2025.08.28

2025.08.28

Industry News

Industry News

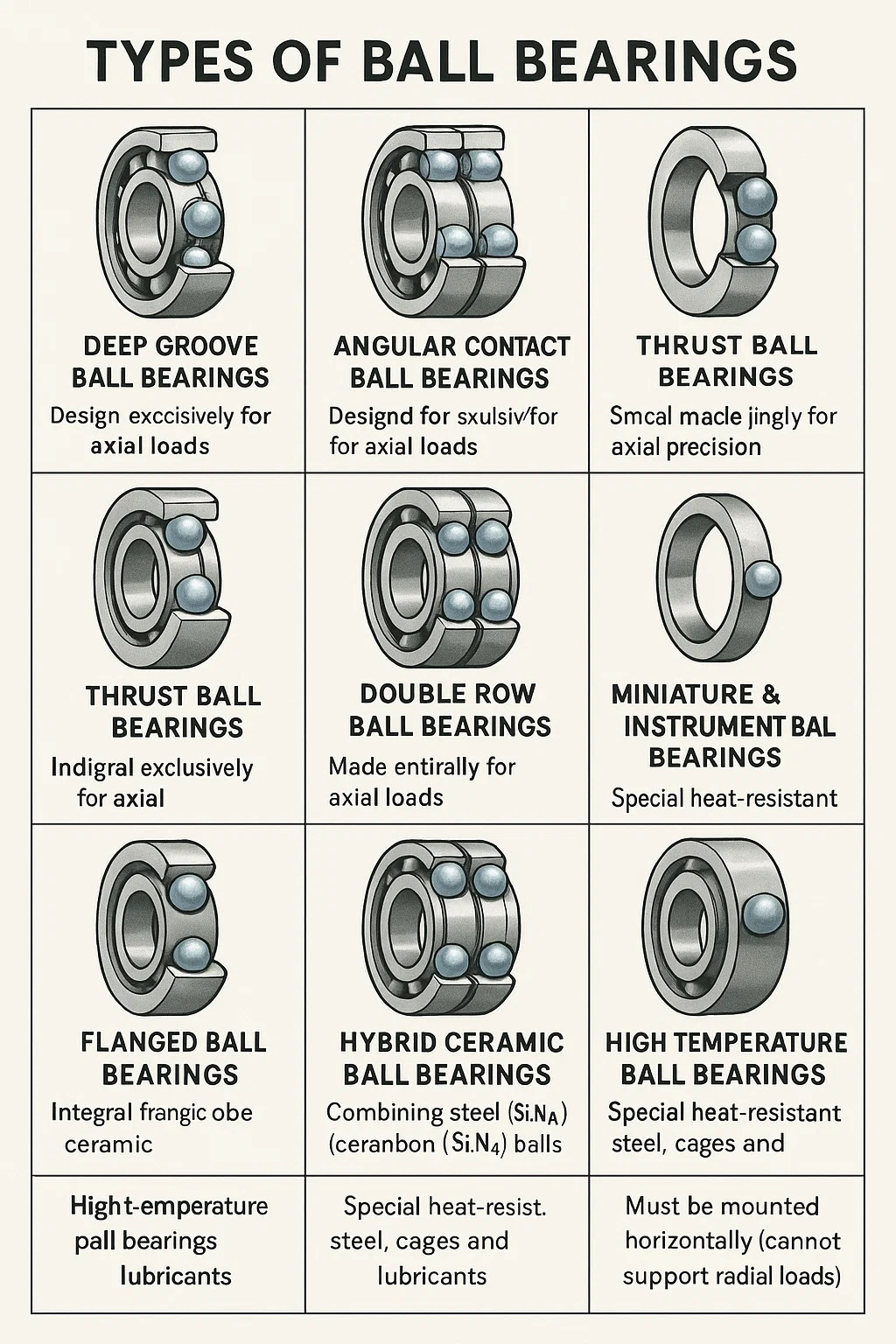

Types of Ball Bearings

1. Deep Groove Ball Bearings

Design: Simple, versatile, with deep raceways in inner/outer rings.

Load Capacity: Handles radial + moderate axial loads (both directions).

Common Uses: Electric motors, appliances, automotive components.

Key Feature: Most widely used; cost-effective for general purposes.

2. Angular Contact Ball Bearings

Design: Asymmetric raceways; designed for combined loads (radial + axial).

Load Capacity: High unidirectional axial load capacity (depends on contact angle).

Common Uses: Machine tool spindles, pumps, gearboxes.

Key Feature: Often used in pairs (back-to-back or face-to-face) to handle thrust in both directions.

3. Self-Aligning Ball Bearings

Design: Outer ring has a spherical raceway, allowing misalignment compensation.

Load Capacity: Primarily radial; limited axial load capacity.

Common Uses: Applications with shaft deflection (e.g., long shafts, conveyor systems).

Key Feature: Tolerates misalignment (up to 3°), reducing stress.

4. Thrust Ball Bearings

Design: Designed exclusively for axial loads (no radial load capacity).

Types:

Single-direction: Handles thrust in one direction.

Double-direction: Manages thrust in both directions.

Common Uses: Automotive steering systems, crane hooks, vertical shafts.

Key Feature: Must be mounted horizontally (cannot support radial loads).

5. Double Row Ball Bearings

Design: Two rows of balls for higher radial load capacity than single-row bearings.

Load Capacity: Handles heavy radial loads but limited axial capacity.

Common Uses: Industrial gearboxes, heavy machinery.

Key Feature: More rigid than single-row bearings but less tolerant of misalignment.

6. Miniature & Instrument Ball Bearings

Design: Extremely small (1mm+ bore), high precision.

Load Capacity: Light loads only (radial + minimal axial).

Common Uses: Medical devices, robotics, small motors, drones.

Key Feature: Optimized for high-speed, low-noise applications.

7. Flanged Ball Bearings

Design: Features an integral flange for easy mounting/alignment.

Load Capacity: Similar to deep groove bearings.

Common Uses: Linear motion guides, conveyor rollers.

Key Feature: Simplifies installation by eliminating the need for separate housings.

8. Hybrid Ceramic Ball Bearings

Design: Combines steel rings + ceramic (Si3N4) balls.

Load Capacity: Similar to steel bearings but with higher speed capability.

Common Uses: High-speed spindles, aerospace, racing applications.

Key Feature: Reduced friction, heat resistance, electrical insulation.

9. Stainless Steel Ball Bearings

Design: Made entirely from corrosion-resistant stainless steel (304/316/440C).

Load Capacity: Lower than chrome steel bearings but resists rust/chemicals.

Common Uses: Food processing, marine, medical, and chemical industries.

Key Feature: No coating flaking (hygienic for sensitive environments).

10. High-Temperature Ball Bearings

Design: Uses special heat-resistant steel, cages, and lubricants.

Load Capacity: Standard radial/axial, but operates at 200°C+.

Common Uses: Furnaces, industrial ovens, turbochargers.

Key Feature: Prevents lubricant breakdown & material warping under heat.