Stainless steel bearings are widely used and have advantages over regular bearings due to their corrosion resistance, acid-alkali resistance, rust prevention, and wide temperature range applicability. They find applications in environments with complex and harsh conditions such as food processing machinery (juicers, food mixers), household appliances, medical equipment, and other demanding fields.

NBVO currently produces stainless steel bearings that meet V2 and V3 levels.

Key technologies include:

Precision Level P5: Improving machining processes, incorporating additional heat treatment quenching followed by cold treatment at temperatures of -75 to -80 ℃ for 1 to 1.5 hours to ensure high dimensional stability of the inner and outer rings.

Low Noise: Employing a dual-stage groove process using imported oil stones to maintain machining benchmarks, enhancing roughness of the inner and outer ring channels, ultimately maintaining stainless steel bearing noise within the Z2 range.

Material Selection: Using highly corrosion-resistant stainless steel materials for inner and outer rings, steel balls, cages, and dust covers. SUS440 is used for inner and outer ring materials and steel balls, while SUS304 is used for cages and dust covers.

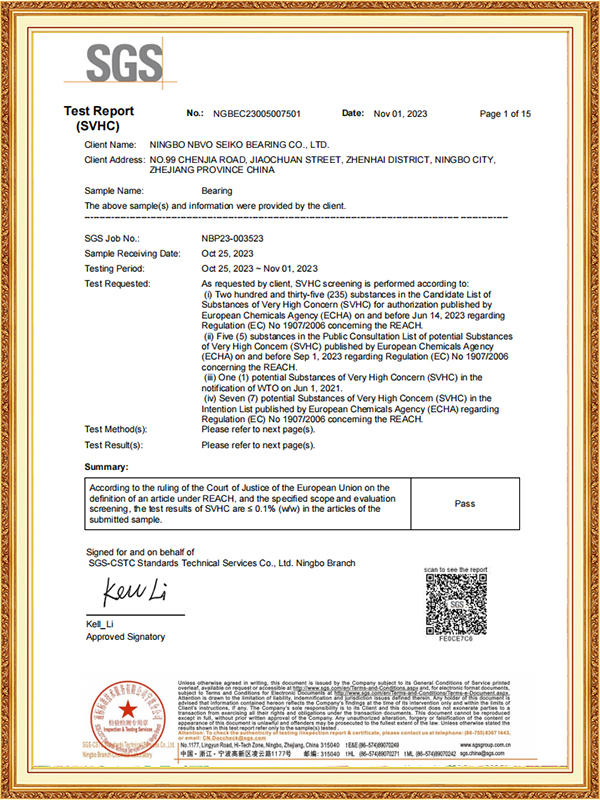

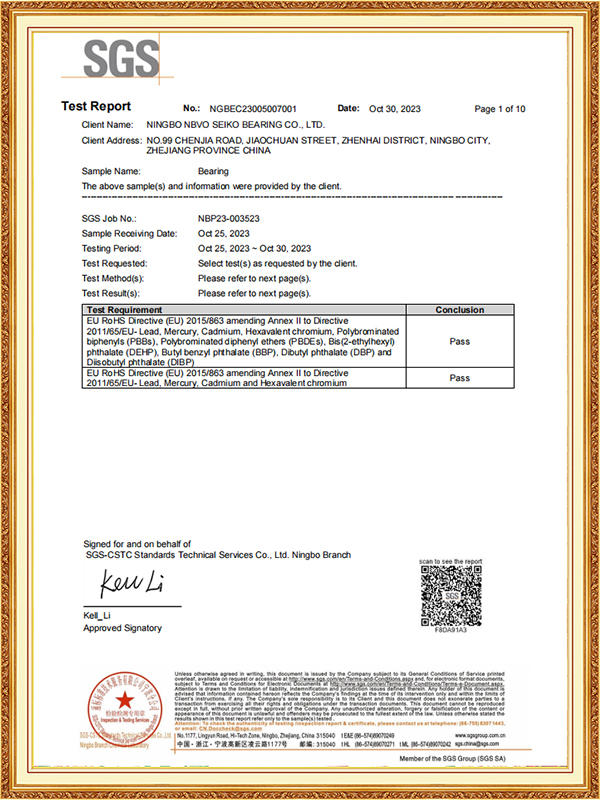

Choosing high-purity, low-noise grease that meets food-grade certification requirements, ensuring that precision stainless steel bearings comply with international environmental standards.