Different usage environments indeed require the selection of different types of stainless steel ball bearings to ensure optimal performance, lifespan, and safety. The following is a point by point int...

View MoreStainless steel ball bearings can be used in ovens, but the selection should be based on the specific operating conditions of the oven. The following are the advantages and precautions of their applic...

View MoreThe application of stainless steel ball bearings in surgical instruments has certain advantages. The following points introduce their applicability and characteristics: 1. Strong corrosion resistance,...

View MoreInnovation and application of stainless steel ball bearings!

1. Why have stainless steel ball bearings become the "invisible guardian" of high-end industrial fields?

Stainless steel ball bearings have become core components in food processing, medical equipment, chemical industry and other fields due to their corrosion resistance, high strength and low maintenance requirements. For example, in food machinery, stainless steel can avoid contamination of products due to rust, and Ningbo NBVO Seiko Bearing Co., Ltd has further improved the durability and hygiene standards of bearings through SUS304/316 stainless steel materials and precision manufacturing processes.

2. How does NBVO define the "precision ceiling" of stainless steel bearings through technological innovation?

NBVO uses modern high-precision equipment and precision processes of level 6 and above to produce deep groove ball bearings with noise levels of ZV3 (stainless steel) and ZV4 (chrome steel). Its patented technologies such as **"bearing polishing fixture" and "grinding device"** significantly reduce processing deflection and ensure the geometric accuracy of the inner and outer rings of the bearings by optimizing clamping stability and grinding efficiency.

3. How to achieve low noise performance of stainless steel ball bearings? What does this mean for industrial applications?

Low noise bearings need to make breakthroughs in three aspects: material purity, raceway smoothness and assembly accuracy. NBVO reduces steel impurities through vacuum degassing smelting technology, combined with fully automatic grinding equipment and acoustic detection systems, so that product noise control reaches the industry-leading level. This feature enables it to greatly reduce vibration interference in scenarios such as motors and precision instruments, and improve equipment life.

4. From international certification to market competitiveness, what is NBVO's "quality code"?

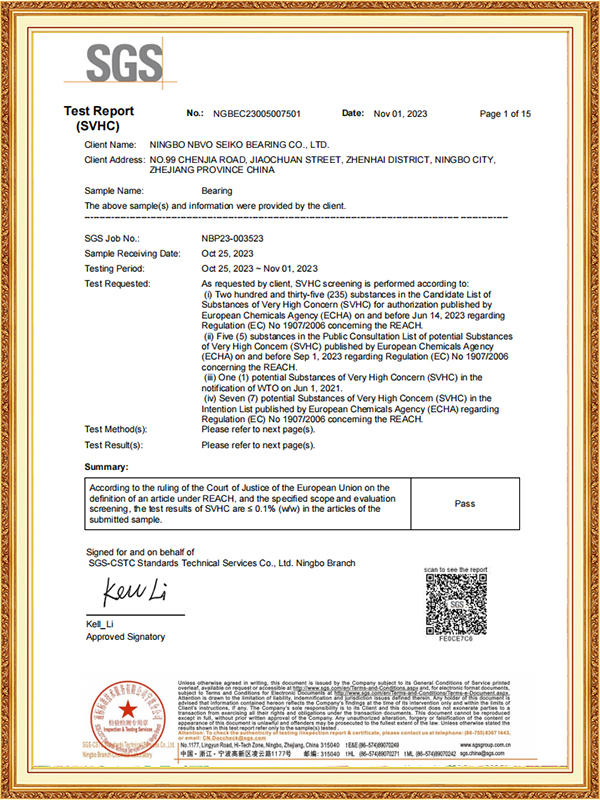

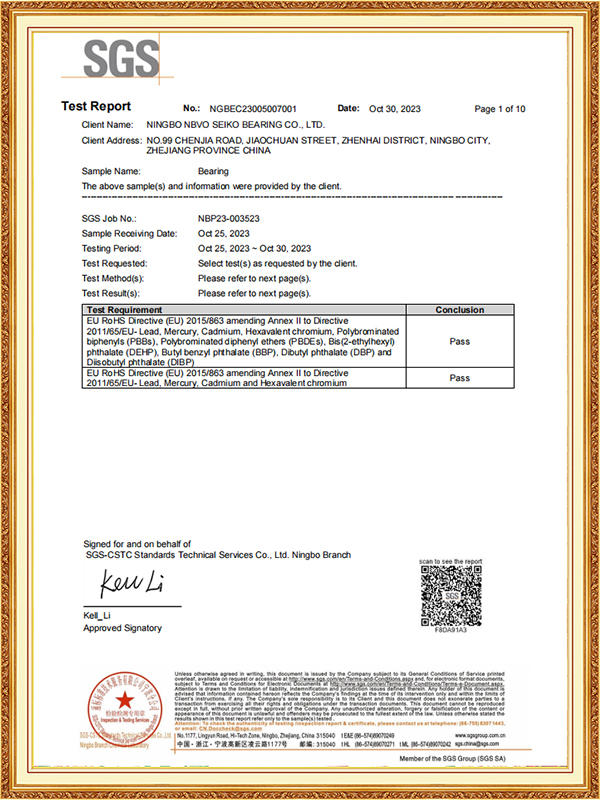

The company strictly follows global standards such as ISO 9001:2015 and IATF 16949:2016, and has passed ROHS and REACH environmental certifications to ensure that its products meet EU environmental protection requirements. Its core advantage lies in the **"high cost-effectiveness"** strategy - using automated production lines to reduce manufacturing costs while maintaining the performance stability of precision bearings, becoming the preferred supplier of domestic and foreign automobile and CNC machine tool manufacturers.

5. How will stainless steel bearings break through application boundaries in the future? What insights does NBVO's technical layout give?

With the growing demand for extreme temperature resistance and lightweight bearings in emerging fields such as new energy and robots, NBVO has laid out low-temperature resistant lubrication technology and thin-walled bearing research and development. Its patented achievements, such as the "adjustable linkage grinding device", not only improve production efficiency, but also provide technical reserves for customized bearing development, and promote the industry to upgrade to intelligence and greenness.

Want to learn more about the technical details of stainless steel ball bearings or NBVO's product solutions? Welcome to get the latest news through the official website. Website