When selecting stainless steel ball bearings, careful consideration must be given to their accuracy. Accuracy directly affects the performance and applicable scenarios of bearings. The following are k...

View MoreWhen choosing stainless steel ball bearings, ensuring size matching is absolutely crucial. Here are several core reasons: Installation feasibility:The bearing must be able to be smoothly installed int...

View MoreDifferent usage environments indeed require the selection of different types of stainless steel ball bearings to ensure optimal performance, lifespan, and safety. The following is a point by point int...

View MoreIn-depth Q&A about thin section ball bearings and Ningbo NBVO Seiko Bearing Co., Ltd

1. What is a thin-walled ball bearing? What are its core advantages?

Thin section ball bearings are a type of bearing with a small inner diameter to outer diameter ratio. They are characterized by extremely thin wall thickness and compact structure, and can achieve high-precision, low-friction rotation performance in a limited space. Through optimized design, this type of bearing not only reduces the overall weight but also improves the load-bearing capacity. It is especially suitable for scenarios with extremely high requirements for lightweight and miniaturization, such as robot joints, medical equipment, and aerospace instruments.

Ningbo NBVO Seiko Bearing Co., Ltd. has independently developed and adopted high-precision processing technology to produce thin section ball bearings with outstanding low noise and long life, meeting the stringent requirements of high-end equipment for stability and reliability.

2. In what fields are thin section ball bearings irreplaceable?

Thin section ball bearings are widely used in:

Industrial robots: used for joint drive to ensure high-speed and high-precision movement;

Medical equipment: such as MRI machines and precision surgical instruments, which rely on their low vibration characteristics;

Semiconductor equipment: achieve dust-free operation in a clean environment to reduce pollution risks;

Aerospace: meet the lightweight and high-temperature resistance requirements under extreme working conditions.

Ningbo NBVO Seiko Bearing Co., Ltd's products have been successfully used in automotive motors, CNC machine tool spindles and other fields, and have been exported to markets such as Europe, the United States, and Japan, verifying its international competitiveness.

3. How to ensure the high quality of thin section ball bearings?

The manufacturing of thin section ball bearings must follow strict standards, such as:

Material selection: use Gcr15 bearing steel or 440C stainless steel to ensure wear resistance and fatigue resistance;

Process control: optimize hardness distribution through heat treatment to reduce deformation;

Detection system: including dynamic load testing, vibration analysis and sealing performance verification.

Ningbo NBVO Seiko Bearing Co., Ltd relies on its own laboratories and advanced testing equipment to implement ISO9001 and IATF16949 quality management systems, and monitors the entire process from raw materials to finished products to ensure that the dimensional tolerance and performance of each set of bearings meet the standards.

4. What technical support is needed for the research and development of thin section ball bearings?

The research and development of thin section ball bearings requires the following technical difficulties:

Structural optimization: balance wall thickness and load-bearing capacity through finite element analysis;

Lubrication design: use grease lubrication or oil lubrication solutions to reduce friction loss;

Seal innovation: develop dust-proof and leak-proof sealing structures to extend service life.

Ningbo NBVO Seiko Bearing Co., Ltd relies on a strong R&D team to customize and develop according to customer drawings or samples, and continuously iterate products by combining simulation technology and actual testing to meet diverse needs.

5. How does Ningbo NBVO Seiko Bearing Co., Ltd stand out in the international market?

As a company specializing in the production of high-precision bearings, Ningbo NBVO Seiko Bearing Co., Ltd's core competitiveness is reflected in:

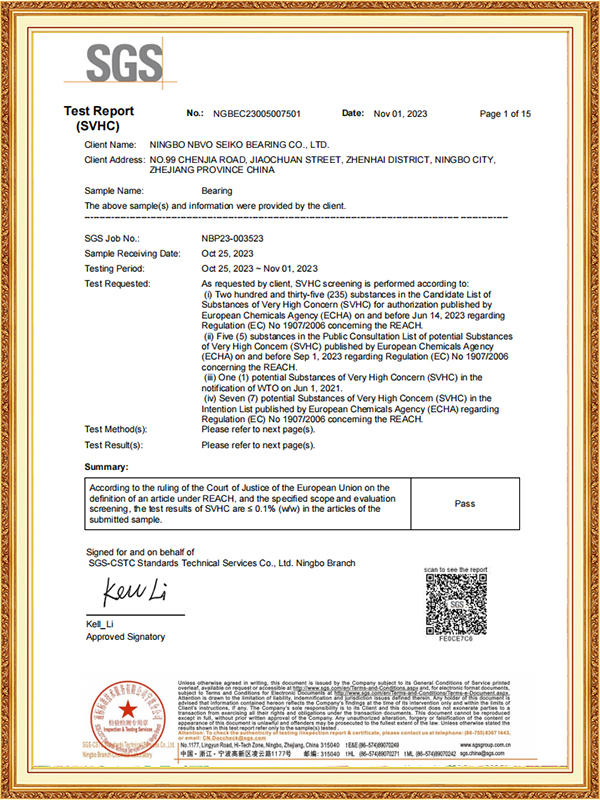

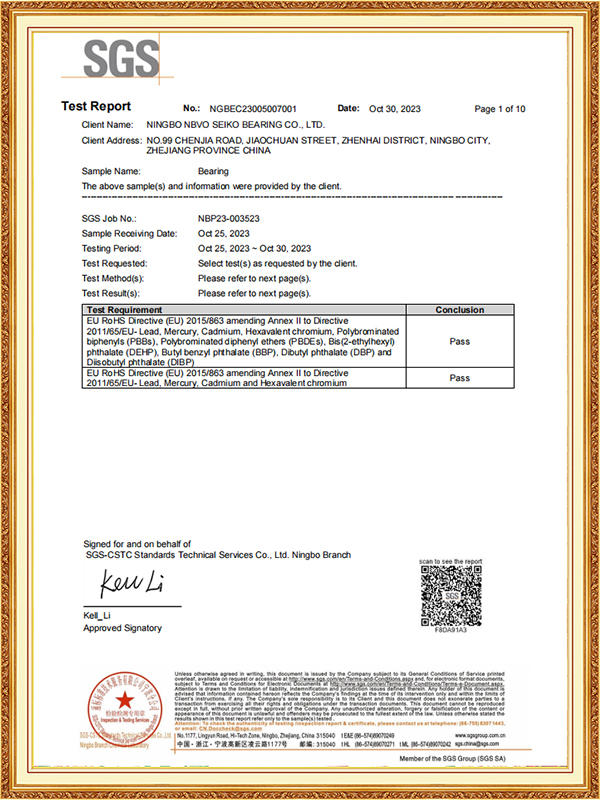

Technology accumulation: It has independent laboratories and patented processes, and its products comply with international environmental protection directives such as RoHS and Reach;

Quick response: Relying on a rich inventory of standard raw materials, shortening the delivery cycle, and flexibly responding to customer needs;

Global layout: Deeply cultivating the high-end markets in Europe, the United States and Japan, and continuously expanding emerging fields such as semiconductor equipment and new energy. Through continuous innovation and quality control, the company is steadily moving towards the goal of "benchmarking brand in China's bearing industry".

For further information on product details or cooperation directions, you can obtain more information through the official website or public contact channels. Website