2025.09.02

2025.09.02

Industry News

Industry News

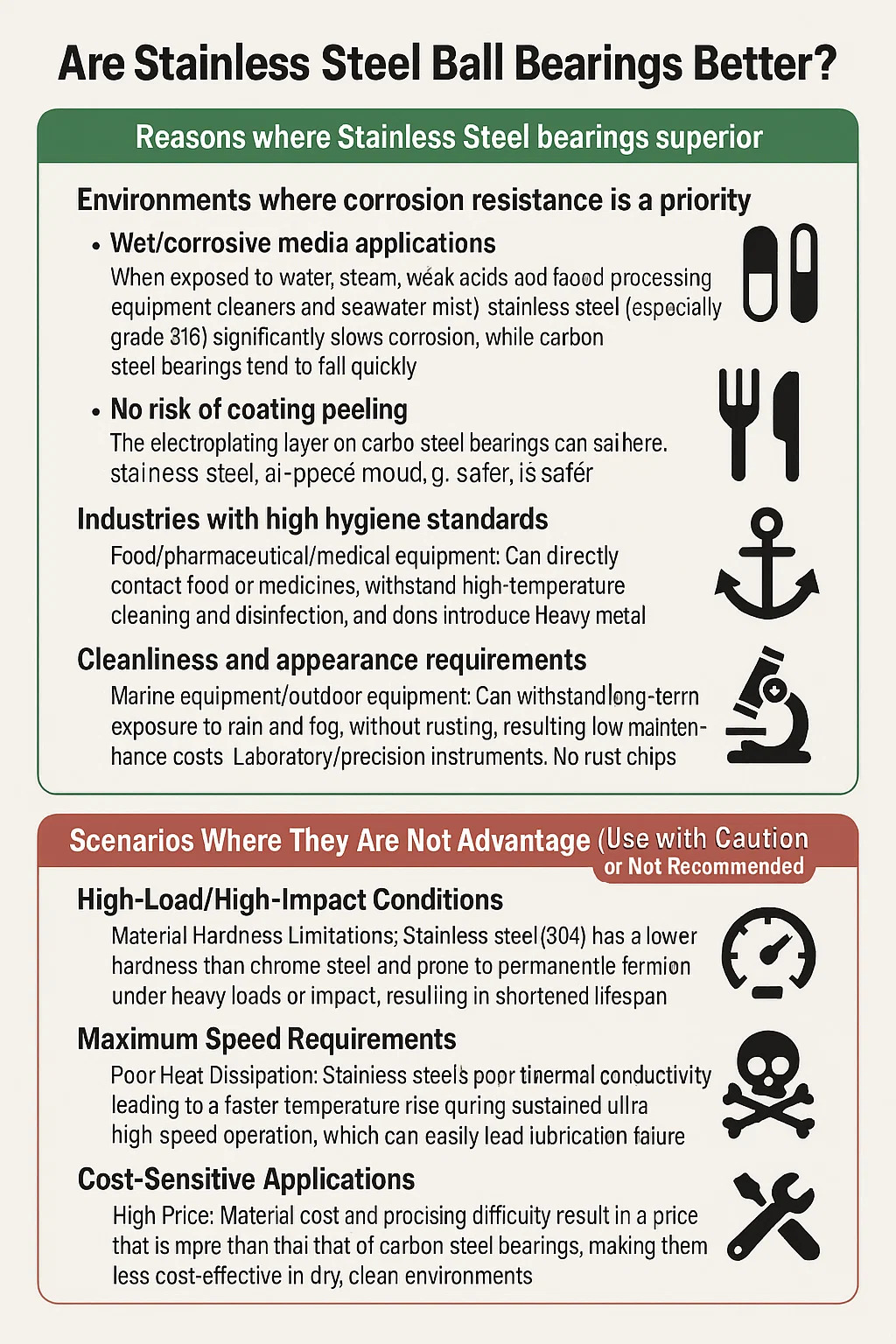

Are stainless steel ball bearings better? — It all depends on the application.

▸ Scenarios where stainless steel bearings are clearly superior (Reasons for choosing stainless steel bearings)

• Environments where corrosion resistance is a priority

Wet/corrosive media applications: When exposed to water, steam, weak acids and bases (such as food processing equipment cleaners and seawater mist), stainless steel (especially grade 316) significantly slows corrosion, while carbon steel bearings tend to fail quickly.

No risk of coating peeling: The electroplating layer on carbon steel bearings can peel and contaminate the product. Stainless steel, one-piece molding, is safer.

• Industries with high hygiene standards

Food/pharmaceutical/medical equipment: Can directly contact food or medicines, withstand high-temperature cleaning and disinfection, and does not introduce heavy metal contamination.

• Cleanliness and appearance requirements

Marine equipment/outdoor equipment: Can withstand long-term exposure to rain and fog without rusting, resulting in low maintenance costs.

Laboratory/precision instruments: No rust chips that could contaminate sensitive environments.

▸ Scenarios Where They Are Not Advantageous (Use with Caution or Not Recommended)

• High-Load/High-Impact Conditions

Material Hardness Limitations: Stainless steel (304/316) has a lower hardness than chrome steel and is prone to permanent deformation under heavy loads or impact, resulting in a shortened lifespan.

• Maximum Speed Requirements

Poor Heat Dissipation: Stainless steel has poor thermal conductivity, leading to a faster temperature rise during sustained ultra-high-speed operation, which can easily lead to lubrication failure or seizure.

• Cost-Sensitive Applications

High Price: Material cost and processing difficulty result in a price that is more than twice that of carbon steel bearings, making them less cost-effective in dry, clean environments.

• Special Corrosive Media

Chloride Ion/Strong Acid Awareness: Saltwater swimming pool equipment and hydrochloric acid environments may cause pitting and perforation, requiring the use of Hastelloy or ceramic bearings.

• Rough Installation/Maintenance Scenarios

Soft and easily damaged: Improper installation and knocking can cause scratches; inferior grease accelerates corrosion.

Stainless Steel Ball Bearings: Selection Guide

| Application Scenario | Choose SS? | Key Reasons |

| Constant moisture/steam/chemical washdown | Essential | Carbon steel rusts rapidly; SS resists water/weak chemicals |

| Food/pharma/medical equipment | Mandatory | Hygienic compliance; no coating flaking or toxic contamination |

| Mild corrosion + moderate loads | Recommended | Balances corrosion resistance with sufficient durability |

| Dry environments + heavy loads | Avoid | Higher cost + lower load capacity vs. chrome steel bearings |

| High-speed rotating spindles | Avoid | Poor heat dissipation → thermal failure risk; chrome steel handles speed better |

| Saltwater/chloride exposure | ️Verify alloy | Standard SS (304/316) may pit; only specific grades (316L) survive with seals |

| Strong acids/oxidizing chemicals | Inadequate | Will corrode; use specialty alloys (Hastelloy) or ceramic bearings |

| Cost-sensitive bulk applications | Poor value | 2-5x cost premium unjustified if no corrosion threat |