2025.09.08

2025.09.08

Industry News

Industry News

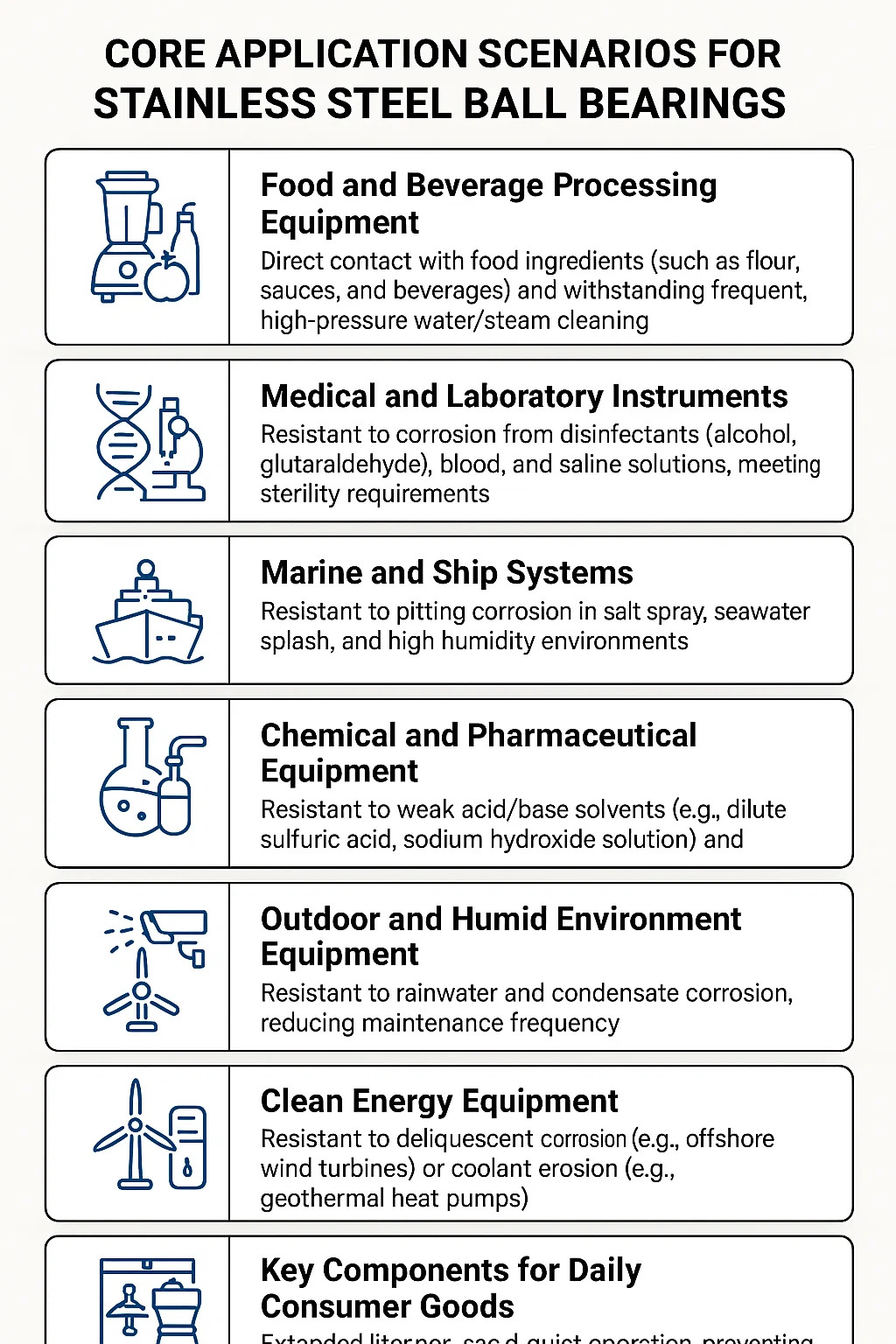

Core Application Scenarios for Stainless Steel Ball Bearings

1. Food and Beverage Processing Equipment

Critical Function: Direct contact with food ingredients (such as flour, sauces, and beverages) and withstanding frequent, high-pressure water/steam cleaning.

Typical Equipment: Blenders, filling machines, conveyor belt bearings, and rollers in baking ovens.

Irreplaceability: Plating loss in conventional bearings can contaminate production lines, while one-piece stainless steel bearings eliminate this risk.

2. Medical and Laboratory Instruments

Critical Function: Resistant to corrosion from disinfectants (alcohol, glutaraldehyde), blood, and saline solutions, meeting sterility requirements.

Typical Equipment: Centrifuge rotors, surgical instrument joints, dialysis machine pump shafts, and DNA analyzer turntables.

Irreplaceability: Rusting of carbon steel bearings can contaminate samples or cause medical accidents.

3. Marine and Ship Systems

Critical Function: Resistant to pitting corrosion in salt spray, seawater splash, and high humidity environments.

Typical Equipment: Marine pump bearings, deck crane pulleys, steering gear transmission components, and fishing vessel winches.

Irreplaceability: Conventional bearings rust within 48 hours after immersion in seawater, while stainless steel bearings can withstand corrosion for months.

4. Chemical and Pharmaceutical Equipment

Key Function: Resistant to weak acid/base solvents (e.g., dilute sulfuric acid, sodium hydroxide solution) and organic vapors.

Typical Equipment: Reactor agitator shafts, metering pump bearings, pipeline valve shafts.

Boundary Reminder: Strong acids (e.g., concentrated hydrochloric acid) can still cause corrosion, requiring replacement with special alloy bearings.

5. Outdoor and Humid Environment Equipment

Key Function: Resistant to rainwater and condensate corrosion, reducing maintenance frequency.

Typical Equipment: Automatic irrigation turntables, pool filter motors, outdoor surveillance pan/tilt heads.

Economical Choice: 316 stainless steel offers superior cost-effectiveness over frequently replaced carbon steel bearings.

6. Clean Energy Equipment

Key Function: Resistant to deliquescent corrosion (e.g., offshore wind turbines) or coolant erosion (e.g., geothermal heat pumps).

Typical Equipment: Tidal turbine sealed bearings, solar tracking bracket shafts, fuel cell compressors.

Industry Essential Need: Equipment can be unmanned year-round, with reliability outweighing cost.

7. Key Components for Daily Consumer Goods

Key Function: Extended lifespan and quiet operation, preventing safety issues caused by rust and seizure.

Typical Equipment: High-end dishwasher arms, coffee maker grinding shafts, and sealed bearings for diving flashlights.

User Experience: Rusted bearings can cause leaks/unusual noises, directly triggering product returns.