2025.09.29

2025.09.29

Industry News

Industry News

Single row deep groove bearings: the "universal screwdriver" of mechanical design

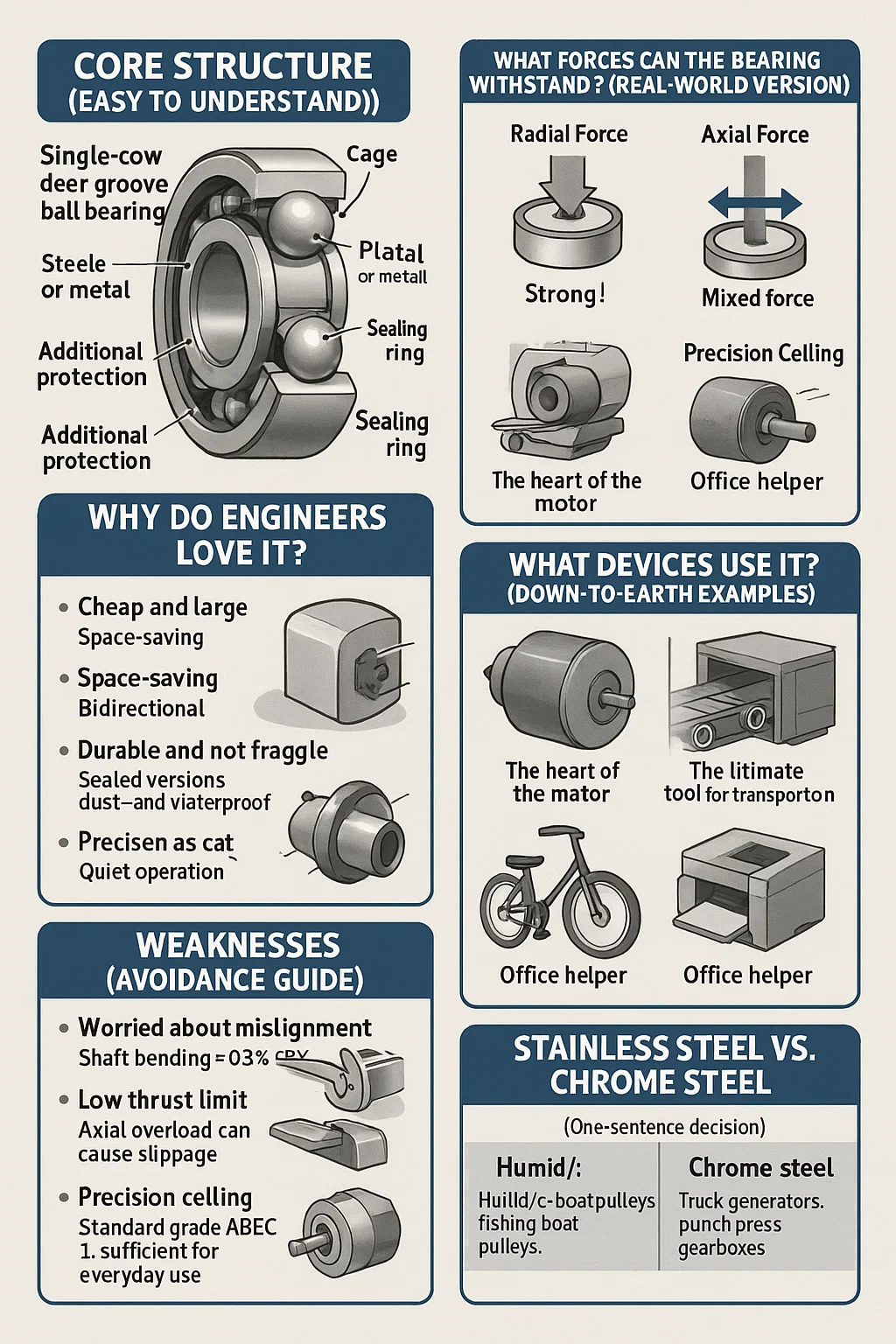

1. Core Structure (Easy to Understand)

Single-row Steel Ball Bearings: A single row of balls is nestled between inner and outer rings, like marbles sandwiched in a ball-like structure.

Deep Groove Bearings: The arc-shaped grooves on the inner and outer rings are deeper than the balls, ensuring a secure grip and smooth rolling motion.

Cages: Plastic or metal cages separate the balls to prevent collisions.

Additional Protection: Dust caps (metal sheets) or sealing rings (rubber lips) can be installed on both sides to prevent dirt and oil leaks.

2. What Forces Can the Bearing Withstand? (Real-World Version)

Radial Force (Force Compressing the Bearing):

Strong! It can easily withstand the weight of a motor rotor and the pressure of conveyor belt cargo.

Example: When a fan blade rotates, the bearing supports the downward pull on the shaft.

Axial Force (Force Pushing the Bearing):

Bidirectional: It can withstand small thrusts, such as the forward force of a power drill when tightening a screw. Warning: Don't let it do the jacking alone—leave the heavy lifting to the thrust bearing!

Mixed Force:

Sufficient for daily use: It can handle forces like turning and cornering a car wheel.

3. Why do engineers love it?

Cheap and large: Simple structure, low mass production cost, saving 30% of the budget compared to fancy bearings.

Space-saving: A thin ring fits into tight spaces (such as power tool gearboxes).

Durable and not fragile: Sealed versions are dust- and waterproof, and can spin a washing machine drum for five years without stalling.

Quiet as a cat: Quiet operation, air conditioner fans and computer fans use it.

4. What devices use it? (Down-to-earth examples)

The heart of the motor: 90% of small motors (refrigerator compressors, power window motors) rely on it to support the rotor.

The lifeblood of the assembly line: The rollers on factory conveyor belts, carrying the pressure of goods and the pull of the belt.

The ultimate tool for transportation: Bicycle hub bearings—they carry your body weight while absorbing pedal thrust. Office Helper: Printer pickup rollers and scanner rails quietly work hard.

5. Weaknesses (Avoidance Guide)

Worried about misalignment: Shaft bending exceeding 0.5° will cause wear (like wheel deviation and tire wear); use self-aligning bearings.

Low thrust limit: Axial overload can cause slippage (such as when a vertical shaft in a water pump pumps water); add thrust washers.

Precision Ceiling: Standard grade (ABEC 1) is sufficient for everyday use, while precision machine tool spindles require the investment of ABEC 5+.

6. Stainless Steel vs. Chrome Steel (One-Sentence Decision)

| Scenario | Choose Stainless | Choose Chrome Steel |

|---|---|---|

| Wet/Corrosive Environments | • Food mixers• Marine pulley systemsEssential for rust-free operation | ― (Not suitable) |

| Dry High-Load Applications | ― (Overkill) | • Truck alternators• Punch press gearboxesSuperior strength/cost ratio |

| Cost-Sensitive Projects | Only when corrosion resistance is mandatoryPay 2-4× premium | Default choiceSpend savings elsewhere in project |