2025.10.09

2025.10.09

Industry News

Industry News

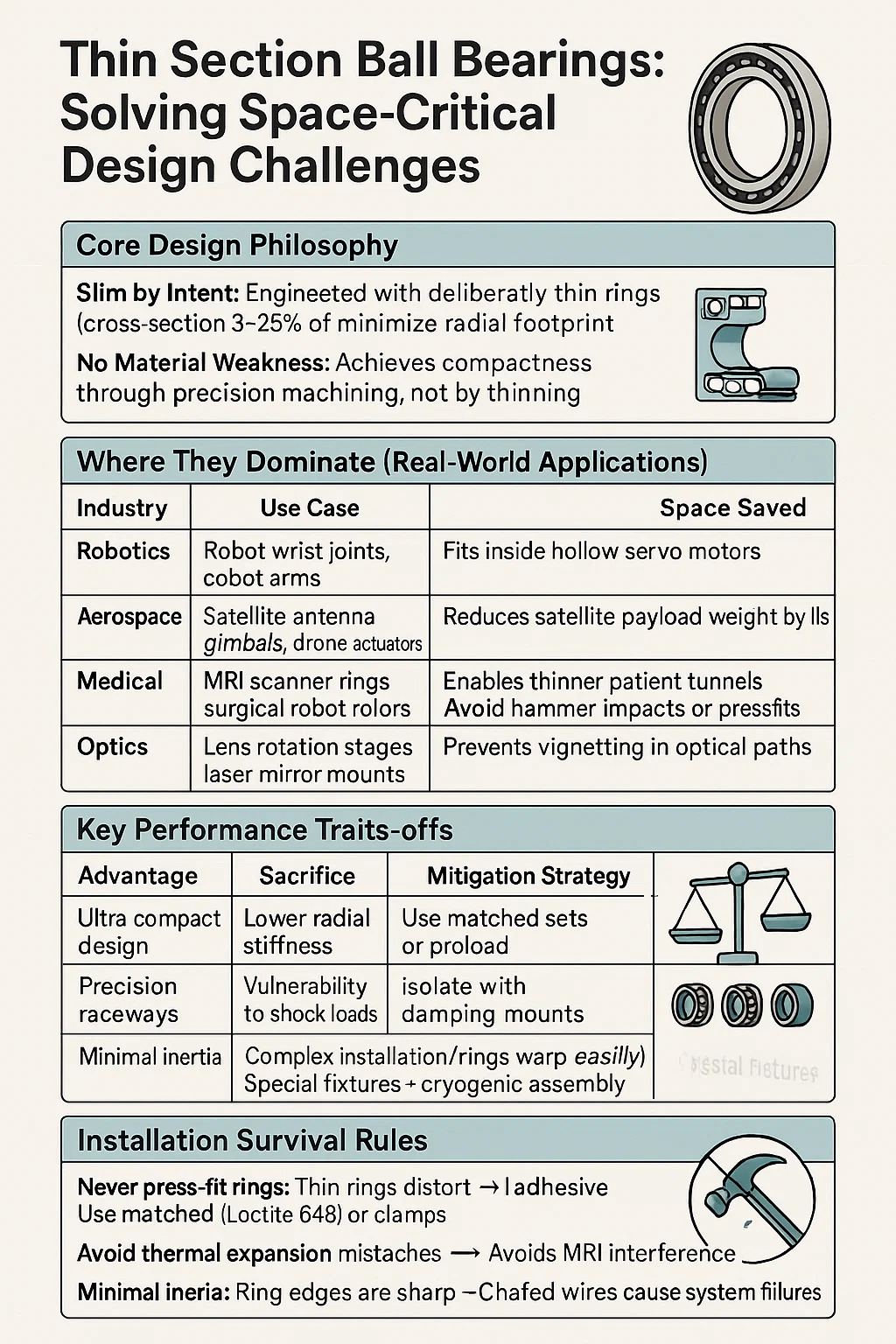

Thin Section Ball Bearings: Solving Space-Critical Design Challenges

1. Core Design Philosophy

"Slim by Intent": Engineered with deliberately thin rings (cross-section 3–25% of bore size) to minimize radial footprint.

No Material Weakness: Achieves compactness through precision machining, not by thinning existing bearings.

2. Where They Dominate (Real-World Applications)

| Industry | Use Case | Space Saved |

|---|---|---|

| Robotics | Robot wrist joints, cobot arms | Fits inside hollow servo motors |

| Aerospace | Satellite antenna gimbals, drone actuators | Reduces satellite payload weight by lbs |

| Medical | MRI scanner rings, surgical robot rotors | Enables thinner patient tunnels |

| Optics | Lens rotation stages, laser mirror mounts | Prevents vignetting in optical paths |

3. Key Performance Traits

Space Efficiency: For a 100mm bore, standard bearing ≈ 140mm OD; thin section ≈ 110mm OD.

Weight Reduction: 50–70% lighter than equivalent standard bearings.

Precision Focus: Typically ABEC 5+ tolerance – mandatory for misalignment-sensitive apps.

Load Limitation: Handles moderate radial loads only – avoid hammer impacts or press fits.

4. Critical Engineering Trade-offs

| Advantage | Sacrifice | Mitigation Strategy |

|---|---|---|

| Ultra-compact design | Lower radial stiffness | Use matched sets or preload |

| Precision raceways | Vulnerability to shock loads | Isolate bearings with damping mounts |

| Minimal inertia | Complex installation (rings warp easily) | Special fixtures + cryogenic assembly |

5. Material Options Dictate Use

Chrome Steel (GCR15): Default for dry/clean environments (e.g., lab equipment).

Stainless Steel (440C): Medical/outdoor use – avoids MRI interference & corrosion.

Hybrid Ceramic: High-speed CT scanners – non-magnetic + electrical insulation.

6. Installation Survival Rules

Never press-fit rings: Thin rings distort → Use adhesive (Loctite 648) or clamps.

Avoid thermal expansion mismatches: Aluminum housings + steel bearings = binding.

Shield cables/wires: Ring edges are sharp – chafed wires cause system failures.