2025.09.22

2025.09.22

Industry News

Industry News

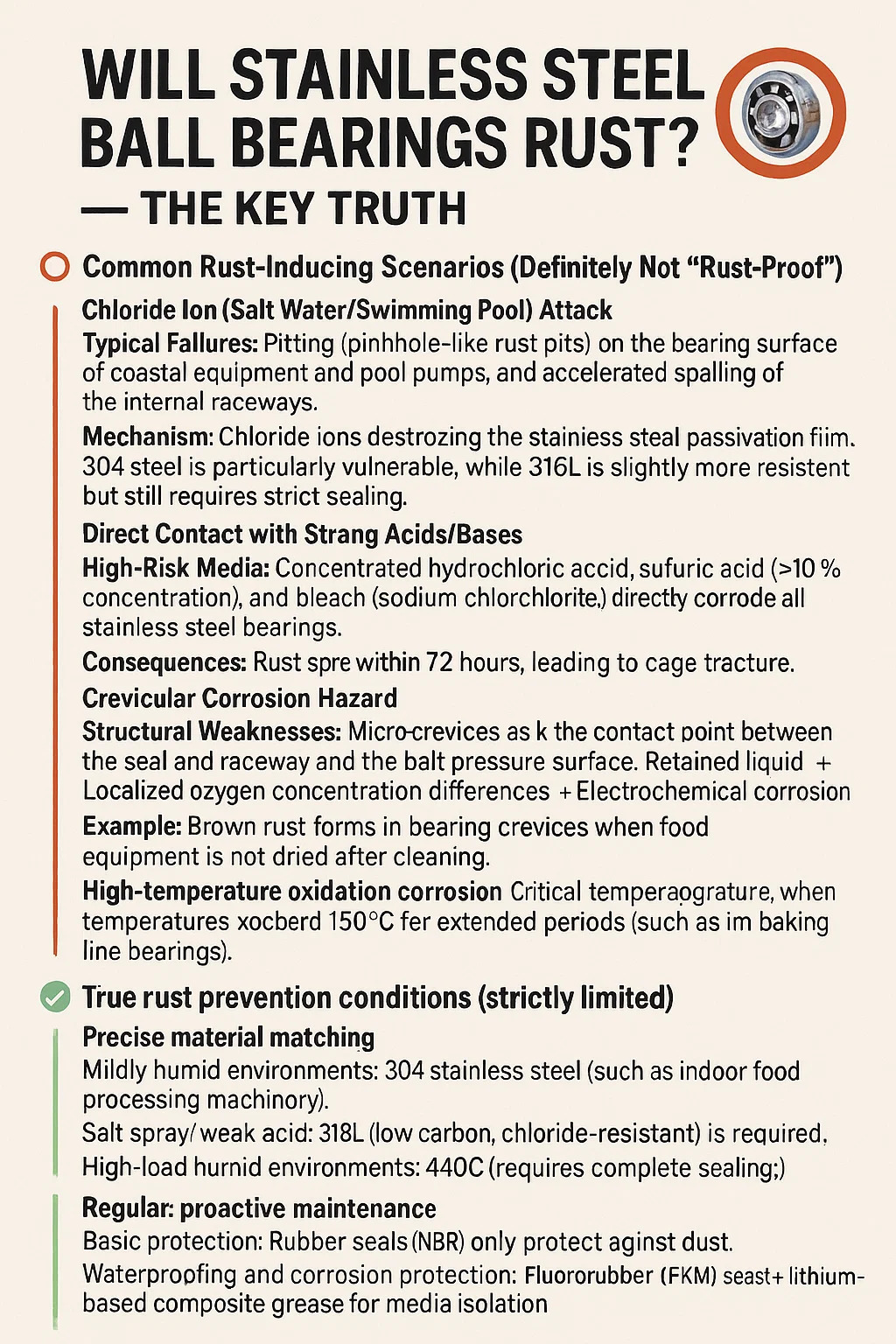

Will stainless steel ball bearings rust? — The Key Truth

⭕ Common Rust-Inducing Scenarios (Definitely Not "Rust-Proof")

--Chloride Ion (Salt Water/Swimming Pool) Attack

Typical Failures: Pitting (pinhole-like rust pits) on the bearing surface of coastal equipment and pool pumps, and accelerated spalling of the internal raceways.

Mechanism: Chloride ions destroy the stainless steel passivation film. 304 steel is particularly vulnerable, while 316L is slightly more resistant but still requires strict sealing.

--Direct Contact with Strong Acids/Bases

High-Risk Media: Concentrated hydrochloric acid, sulfuric acid (>10% concentration), and bleach (sodium hypochlorite) directly corrode all stainless steel bearings.

Consequences: Rust spreads within 72 hours, leading to cage fracture.

--Crevicular Corrosion Hazard

Structural Weaknesses: Micro-crevices such as those at the contact point between the seal and raceway and the bolt pressure surface. Retained liquid → Localized oxygen concentration differences → Electrochemical corrosion.

Example: Brown rust forms in bearing crevices when food equipment is not dried after cleaning.

--High-temperature oxidation corrosion

Critical temperature: When temperatures exceed 150°C for extended periods (such as in baking line bearings), the surface chromium oxide layer fails, yellowing, and then red rust spreads.

--Improper maintenance induces corrosion

Critical mistake: Using carbon steel tools to install bearings causes iron chips to embed into the stainless steel, creating a galvanic effect that accelerates corrosion.

Lubrication failure: Low-quality grease emulsifies in water, losing its barrier function.

⭕ True rust prevention conditions (strictly limited)

--Precise material matching

Mildly humid environments: 304 stainless steel (such as indoor food processing machinery).

Salt spray/weak acid: 316L (low-carbon, chloride-resistant) is required.

High-load humid environments: 440°C (requires complete sealing).

--Sealing technology is not optional

Basic protection: Rubber seals (NBR) only protect against dust.

Waterproofing and corrosion protection: Fluororubber (FKM) seals + lithium-based composite grease for media isolation.

--Regular, proactive maintenance

After cleaning: Blow out water stains in crevices with compressed air. Relubrication: Refill with food-grade waterproof grease (such as Klüber HySyn FG 34) every 6 months.