2025.11.04

2025.11.04

Industry News

Industry News

Content

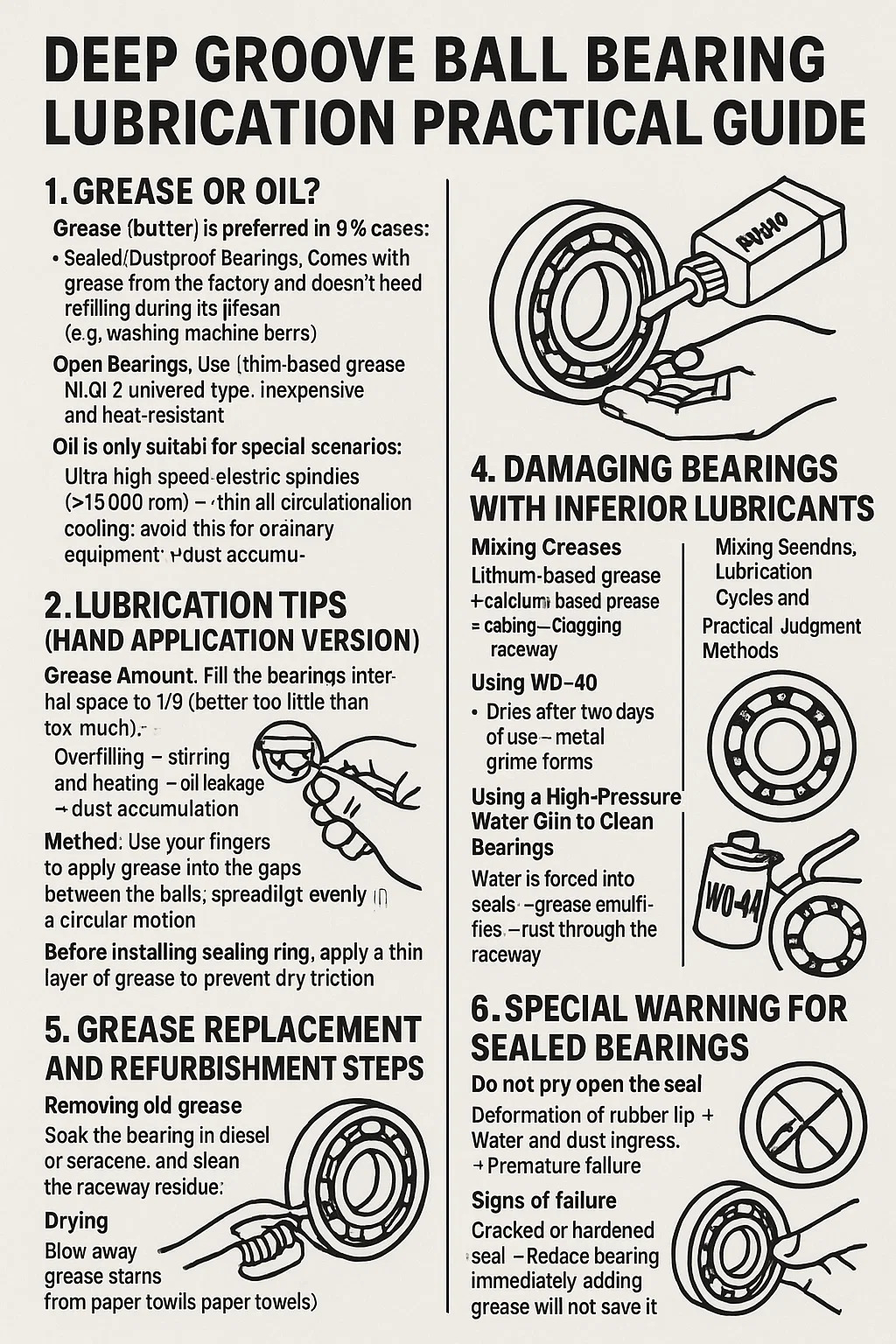

Sealed/Dustproof Bearings: Comes with grease from the factory and doesn't need refilling during its lifespan (e.g., washing machine bearings).

Open Bearings: Use lithium-based grease NLGI 2 universal type, inexpensive and heat-resistant.

Ultra-high speed electric spindles (>15,000 rpm) – use thin oil circulation cooling; avoid this for ordinary equipment.

Grease Amount: Fill the bearing's internal space to 1/3 (better too little than too much):

Overfilling → stirring and heating → oil leakage → dust accumulation.

Method: Use your fingers to apply grease into the gaps between the balls, spreading it evenly in a circular motion.

Before installing the sealing ring, apply a thin layer of grease to the lip to prevent dry friction.

| Application Scenario | Regrease Interval | Real-World Check Method |

|---|---|---|

| Household appliances(Fans, washing machines) | Rarely needed | Replace |

| Factory machinery(Conveyors, motors) | Yearors, motors) | Yearly |

| Farm/construction gear(Tractors, cement mixers) | Every 6 months | Dusty sites: inspect quarterlyReplace if grease turns gritty/black |

Lithium-based grease + calcium-based grease = caking → clogging the raceway.

Dries after two days of use → metal grime forms.

Water is forced into the seals → grease emulsifies → rust through the raceway.

Soak the bearing in diesel or kerosene, and clean the raceway residue with a toothbrush.

Blow away grease stains from gaps with compressed air (or absorb with paper towels). Applying new grease: Apply grease to your finger and insert it between the ball bearings, rotating it a few times to allow it to penetrate.

Deformation of the rubber lip → Water and dust ingress → Premature failure.

Cracked or hardened seal → Replace the bearing immediately; adding grease will not save it.