2025.11.11

2025.11.11

Industry News

Industry News

The Truth About Deep Groove Ball Bearing Alignment Issues

Content

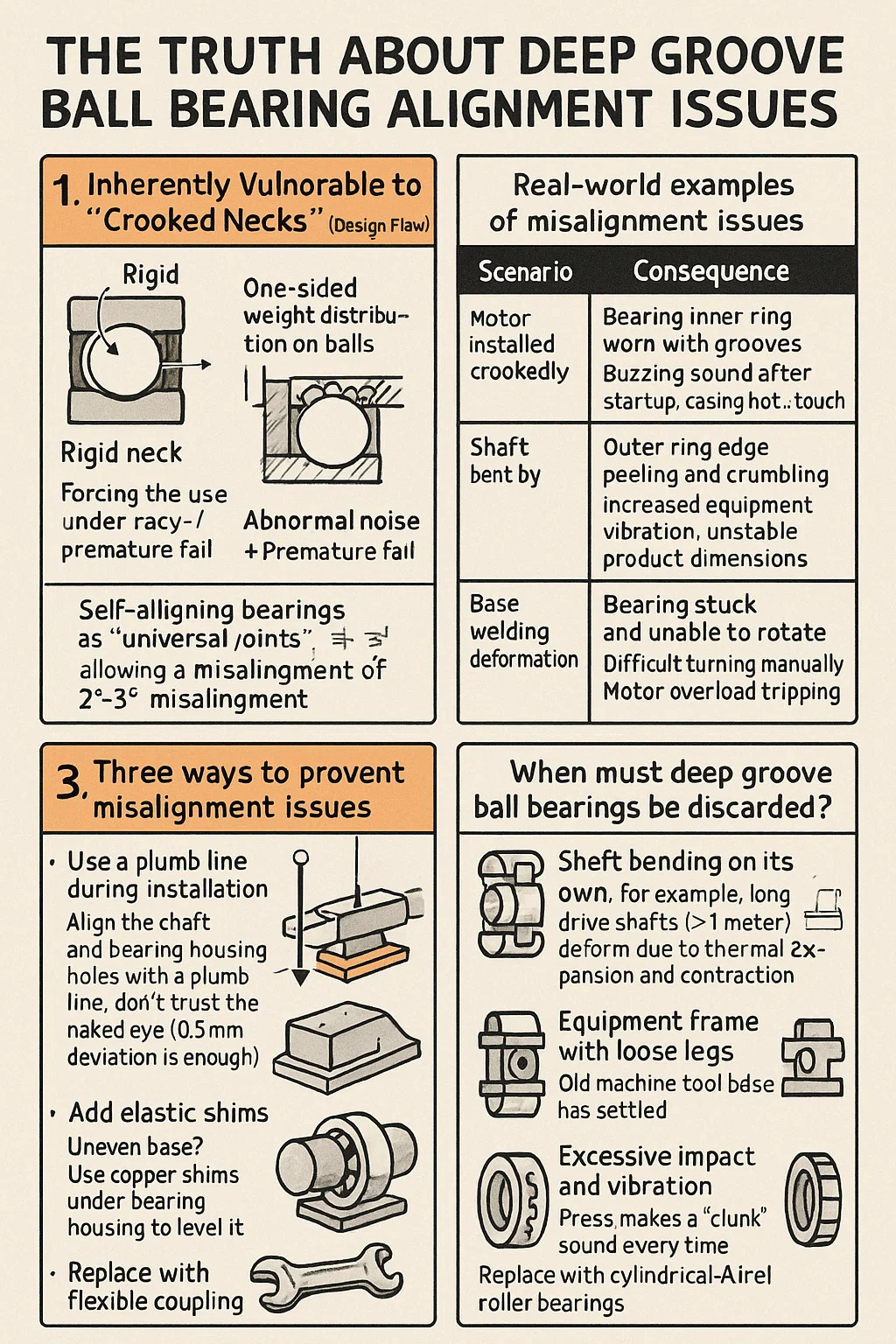

Racecourse Rigid, Rigid Neck: The inner and outer raceways of a deep groove ball bearing are rigid grooves, forcing the balls to run in a straight line.

Slight misalignment of the shaft/bore (e.g., due to misalignment during installation):

One-sided weight distribution on the balls → Dents in the raceway → Abnormal noise + Premature failure.

Comparison: Self-aligning bearings are like "universal joints," allowing for a misalignment of 2°-3°; deep groove ball bearings are "stubborn," failing even with a 0.5° misalignment.

| Scenario | Consequence | How Operators Spot It |

|---|---|---|

| Motor mounted crooked | Inner race gouged like plowed field | Humming like angry bees + Housing hot to touch |

| Belt tension bent shaft | Outer race edges chipping off metal flakes | Machine shakes violently → Parts wobbling out of spec |

| Warped base frame | Bearings lock up solid | Wrench won’t turn shaft → Motor overload trips |

Align the shaft and bearing housing holes with a plumb line; don't trust the naked eye (0.5mm deviation is enough to destroy the bearing).

Uneven base? Use copper shims under the bearing housing to level it; don't force the screws.

Misaligned motor and pump shafts? Use a perforated coupling to absorb vibration; don't let the bearings bear the brunt of the vibration.

Shaft bending on its own: For example, long drive shafts (>1 meter) deform due to thermal expansion and contraction → Replace with self-aligning ball bearings.

Equipment frame with loose legs: The old machine tool base has settled → Replace with spherical roller bearings.

Excessive impact and vibration: The press makes a "clunk" sound every time → Misalignment of the inner and outer rings of the bearing → Replace with cylindrical roller bearings.