2025.10.30

2025.10.30

Industry News

Industry News

Deep Groove Ball Bearing Lifespan: The Real-World Variables

Content

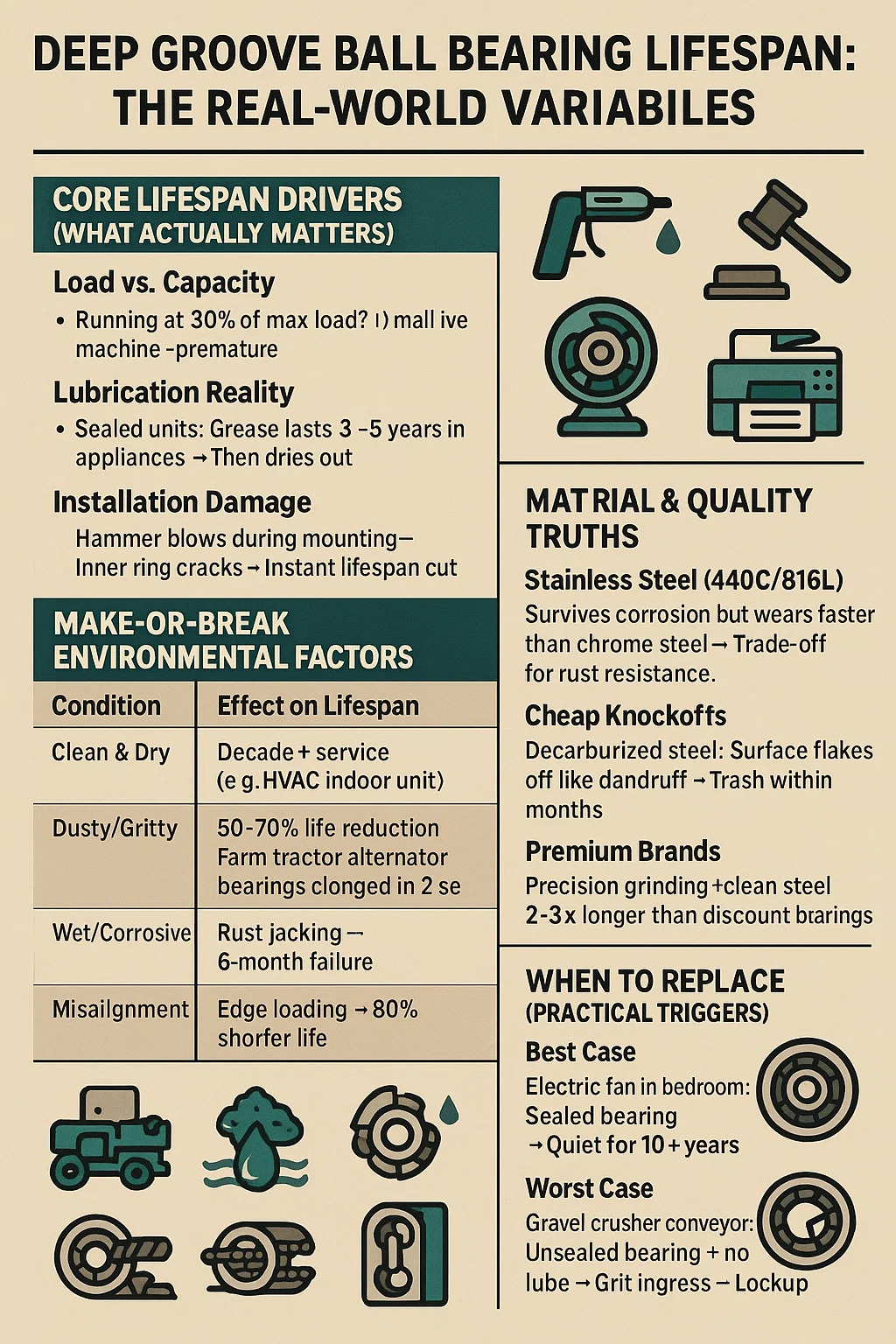

Run at 30% of max load? May outlive the machine.

Consistently >80% load? Expect premature fatigue pits.

Sealed units: Grease lasts 3–5 years in appliances → Then dries out.

Open bearings: Relubricate every 6–12 months or die from grit paste abrasion.

Hammer blows during mounting → Inner ring cracks → Instant lifespan cut by 90%.

| Condition | Effect on Lifespan | Industrial Example |

|---|---|---|

| Clean & Dry | Decade+ service (e.g., HVAC indoor unit) | Office printer bearings spinning for 15 years |

| Dusty/Gritty | 50–70% life reduction | Farm tractor alternator bearings clogged in 2 seasons |

| Wet/Corrosive | Rust jacking → 6-month failure | Car wash conveyor rollers seizing quarterly |

| Misalignment | Edge loading → 80% shorter life | Bent pump shaft eating bearings yearly |

Survives corrosion but wears faster than chrome steel → Trade durability for rust resistance.

Decarburized steel: Surface flakes off like dandruff → Trash within months.

Precision grinding + clean steel → 2–3× longer than discount bearings.

Electric fan in bedroom: Sealed bearing → Quiet for 10+ years → Dies from grease decay.

Gravel crusher conveyor: Unsealed bearing + no lube → Grit ingress → Lockup in 3 weeks.

High-pitch whine: Raceway damage → Replace within hours.

Brown grease: Water contamination → Flush immediately or fail.

Axial play >0.5mm: Shaft wobbles → Accelerates wear exponentially.

Temperature spikes: 70°C+ at housing → Lubricant breaking down → 48-hour countdown.

Vibration spikes: 3× normal amplitude → Balls spalling → Catastrophe imminent.