2025.10.20

2025.10.20

Industry News

Industry News

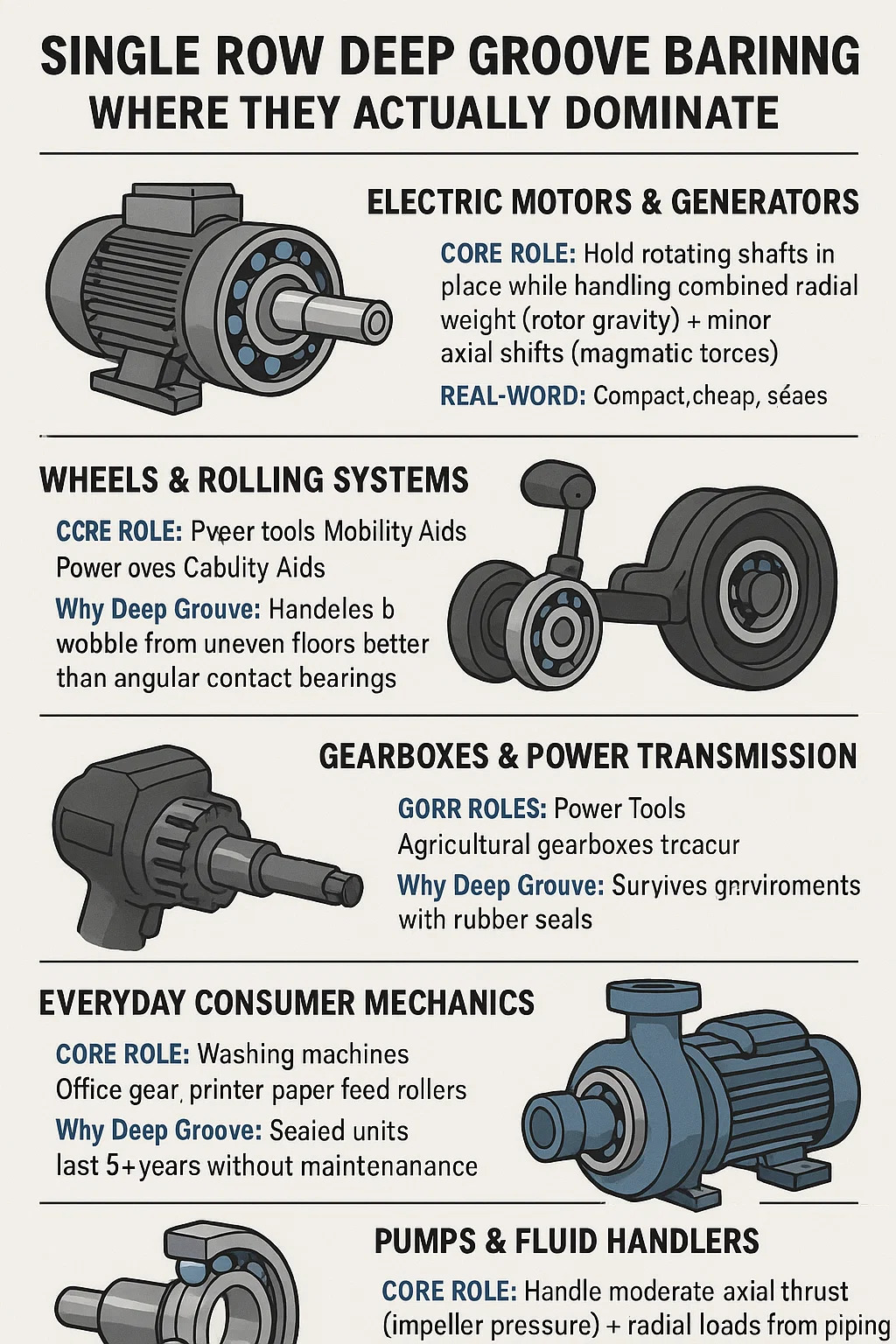

Single Row Deep Groove Ball Bearings: Where They Actually Dominate

Content

Core Role: Hold rotating shafts in place while handling combined radial weight (rotor gravity) + minor axial shifts (magnetic forces).

Real-World Examples:

Household: Vacuum cleaner fans, fridge compressors.

Industrial: Conveyor drive motors, HVAC blowers.

Why Deep Groove?: Compact, cheap, and sealed variants resist dust ingestion.

Core Role: Support radial loads (vehicle/freight weight) while tolerating side forces during turns.

Real-World Examples:

E-Scooters/Mobility Aids: Hub bearings in compact wheels.

Factory Carts: Castor wheels under heavy racks.

Why Deep Groove?: Handles wobble from uneven floors better than angular contact bearings.

Core Role: Absorb gear mesh vibrations + support shafts carrying radial-heavy loads.

Real-World Examples:

Power Tools: Drill gear trains transferring torque.

Agricultural Gearboxes: Tractor PTO shafts.

Why Deep Groove?: Survives gritty environments with rubber seals.

Core Role: Enable smooth rotation in gadgets where space/cost trump extreme precision.

Real-World Examples:

Washing Machines: Drum support bearings resisting soggy laundry imbalance.

Office Gear: Printer paper feed rollers, treadmill running decks.

Why Deep Groove?: Sealed units last 5+ years without maintenance.

Core Role: Handle moderate axial thrust (impeller pressure) + radial loads from piping.

Real-World Examples:

Water Pumps: Household pressure boosters.

Fuel Dispensers: Gas pump rotating assemblies.

Why Deep Groove?: Cost-effective for non-explosive fluids (avoid for acids/abrasives).