2026.01.12

2026.01.12

Industry News

Industry News

Yes, and it's a "professional" at this job!

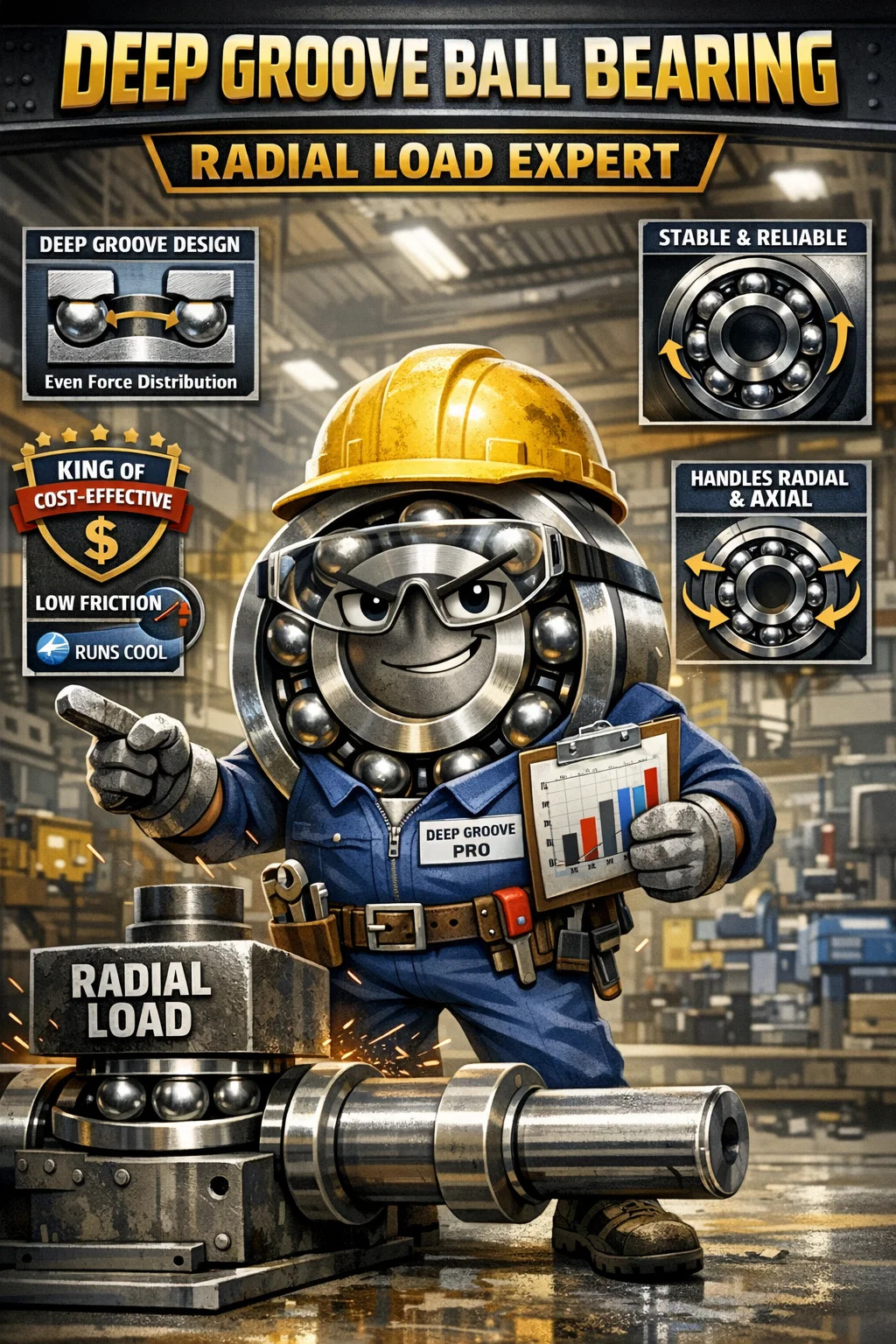

Deep groove ball bearings are primarily designed and best suited for handling radial loads (that is, forces perpendicular to the shaft, like the force of a heavy object pressing down on the shaft).

Content

The design of deep groove ball bearings is very ingenious. The inner and outer rings each have a circular track resembling a "deep groove," and the steel balls are embedded within. When pressure is applied to the shaft from the side, the steel balls are firmly held in the center of the two tracks, resulting in very even force distribution.

Among all bearings capable of handling radial forces, deep groove ball bearings are the most user-friendly.

Low friction: Because the steel balls and tracks have point contact, the rotational resistance is extremely low.

Doesn't overheat: Even at high speeds, it doesn't generate much heat, making it ideal for machines that require long periods of high-speed rotation.

Because the curvature of the tracks matches the steel balls perfectly, the steel balls don't move around when radial force is applied. This stability allows it to be used in a wide range of applications, from household vacuum cleaners to factory electric motors.

Although its main job is to withstand radial forces, because of the depth of the "deep groove," it can also handle some axial force (force pushing the shaft from side to side). This ability to handle both radial and axial loads makes it the most widely used bearing in the world today.