2026.01.05

2026.01.05

Industry News

Industry News

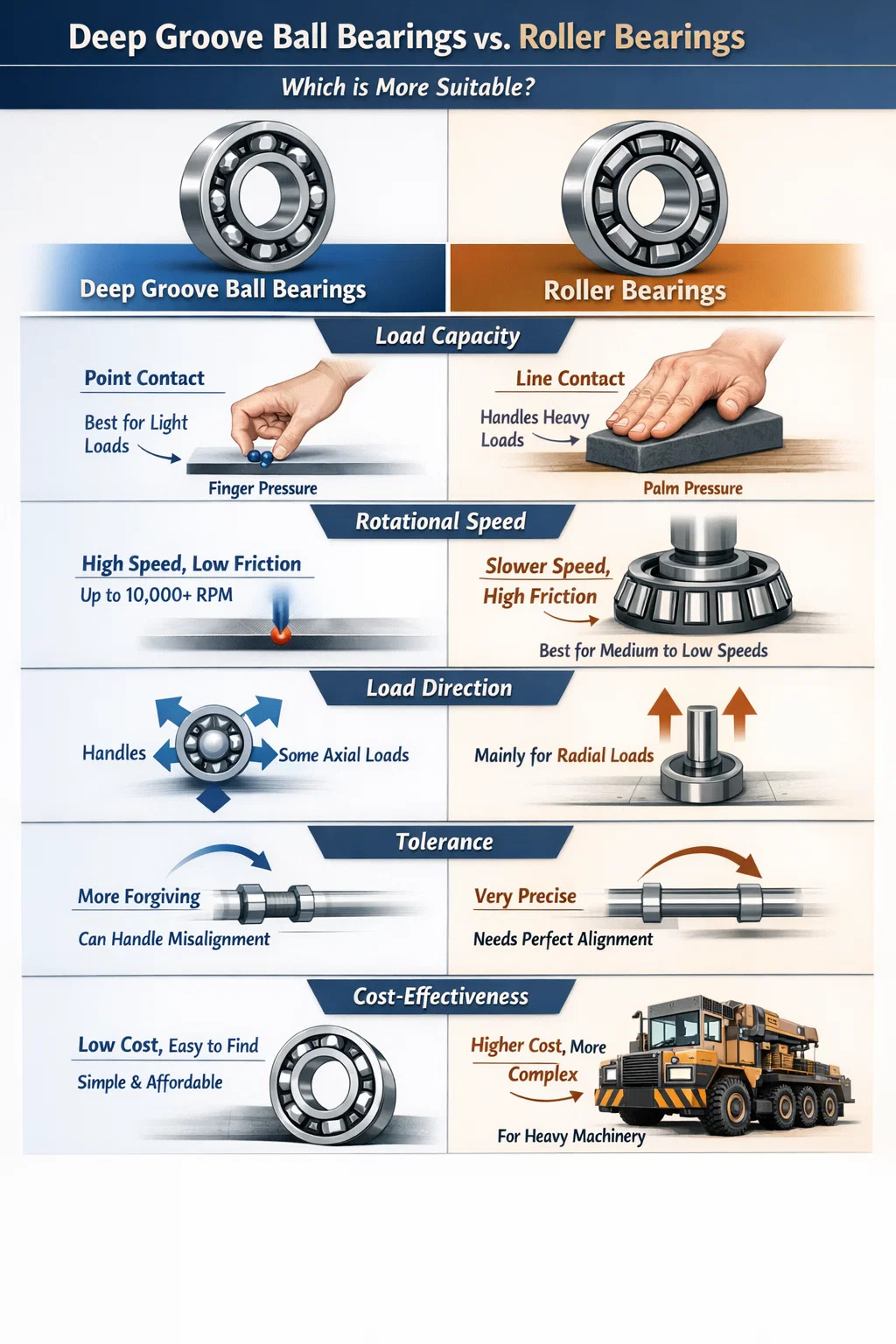

In the world of bearings, there's no absolute "which is better," only "which is more suitable." Deep groove ball bearings and roller bearings are like running shoes and hiking boots – each has its own strengths.

Deep groove ball bearings: The steel balls inside have "point contact," meaning the ball and the raceway only touch at a single point. Therefore, they are suitable for light loads; if you apply too much pressure, that point is prone to deformation.

Roller bearings: The rollers inside are cylindrical or conical, resulting in "line contact." This is like pressing a table with your palm versus pressing it with your finger – the former is stronger. They are very robust and can withstand enormous weight and impact.

Deep groove ball bearings: They excel in having extremely low friction. Because of the small contact area, the resistance to rotation is very low, and less heat is generated. If you need a machine to rotate thousands or even tens of thousands of revolutions per minute (such as a handheld electric drill or a vacuum cleaner motor), they are the first choice.

Roller bearings: Due to the larger contact area, the friction is naturally higher. Although they are very stable, if they rotate at high speed without control, they can easily overheat. Therefore, they are more suitable for medium to low speeds and applications that prioritize stability.

Deep groove ball bearings: They are "all-rounders." They primarily handle vertical pressure (radial load), but because of the deep raceway, they can also withstand some lateral force (axial load).

Roller bearings: They are usually more specialized. For example, cylindrical roller bearings only handle vertical loads; if you push them laterally, they might fall apart. However, special types like tapered roller bearings can withstand large forces in both directions simultaneously.

Deep groove ball bearings: They are quite "forgiving." If the shaft is slightly misaligned, they can still manage to rotate without immediately failing. Roller bearings: Very "fussy." Because they have line contact, they require extremely precise alignment during installation. If the shaft is misaligned, the force will be concentrated on one corner of the roller, leading to rapid damage.

Deep groove ball bearings: Produced in large quantities, with a simple structure, making them inexpensive and easy to purchase. They are the king of cost-effectiveness.

Roller bearings: Have a more complex manufacturing process, and are usually more expensive than ball bearings. They are mainly used in heavy equipment or industrial chassis.

| Requirement / Scenario | Recommended Type |

| Small household appliances & high-speed motors | Deep Groove Ball Bearings |

| Truck hubs, large cranes, & heavy-duty conveyors | Roller Bearings |

| Situations requiring low noise & easy installation | Deep Groove Ball Bearings |

| Environments with heavy vibration & extreme loads | Roller Bearings |

| Light-to-medium loads requiring high precision | Deep Groove Ball Bearings |