2025.12.01

2025.12.01

Industry News

Industry News

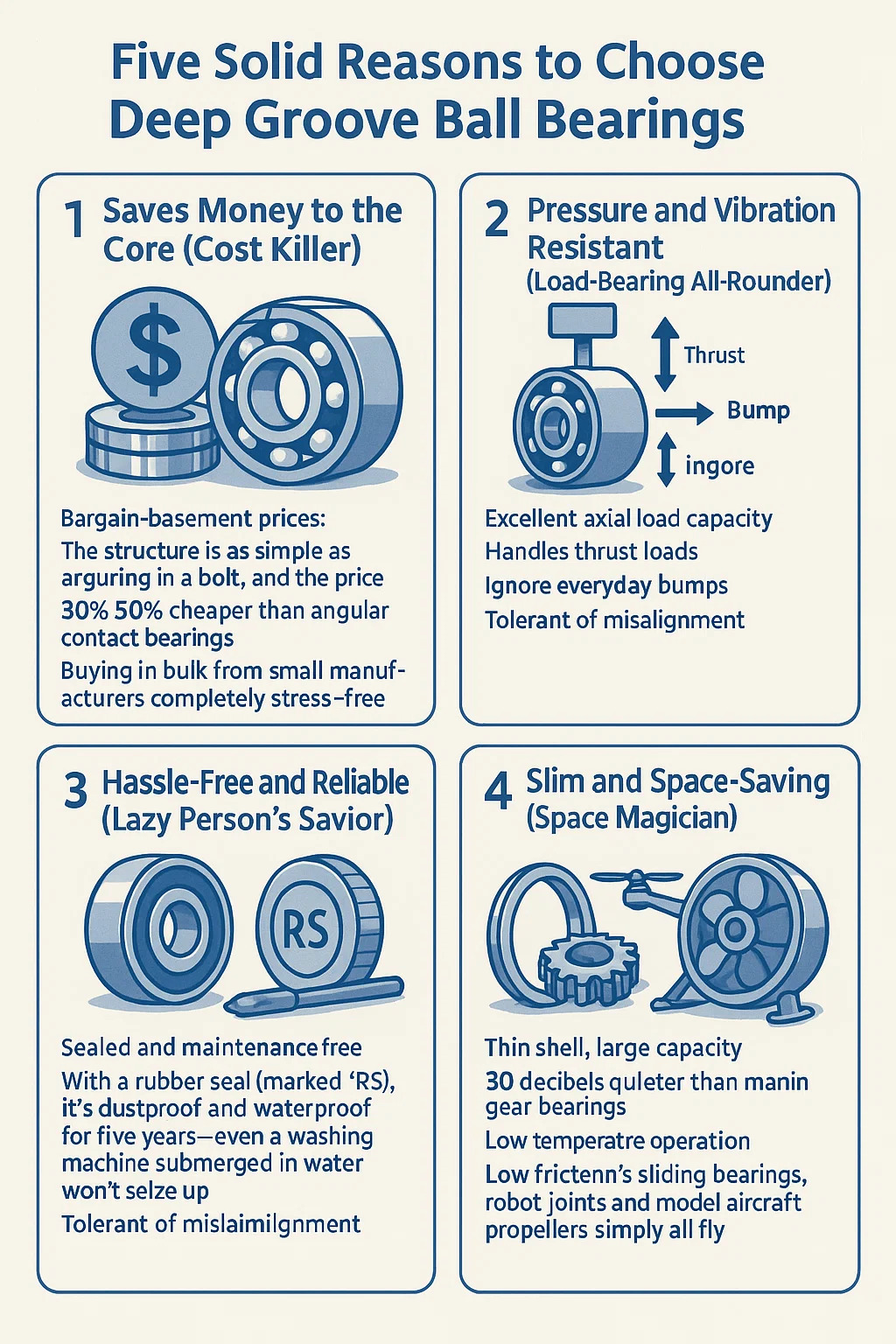

Five Solid Reasons to Choose Deep Groove Ball Bearings:

Content

Bargain-basement prices: The structure is as simple as screwing in a bolt, and the price is 30%-50% cheaper than angular contact bearings. Buying in bulk from small manufacturers is completely stress-free.

Zero burden on inventory: Available everywhere in hardware stores, on Taobao, and in industrial supply stores. Even if your machine breaks down in the middle of the night, you can still get replacement parts.

Excellent axial load capacity: Motor rotor heavy? Conveyor belt carrying heavy goods? Vertical pressure is like a massage to it.

Handles thrust loads as well: The force of a drill bit while drilling, the airflow thrust of a fan blade—it handles small pushes and pulls with ease, eliminating the need for dedicated thrust bearings.

Ignores everyday bumps: Handcart slightly shaking on a rough road? It treats it as free exercise.

Sealed and maintenance-free: With a rubber seal (marked with RS), it's dustproof and waterproof for five years—even a washing machine submerged in water won't seize up.

Low maintenance lubrication: One application of grease lasts a lifetime (for light-load equipment), unlike bronze bushings that need daily lubrication.

Tolerant of misalignment: It still rotates even with an axial misalignment of less than 0.5° (about the thickness of two strands of hair), ten times more forgiving than precision bearings.

Thin shell, large capacity: The outer ring is as thin as a coin, fitting into electric hammer gearboxes and drone motors without taking up any space.

Lightweight champion: Half the weight of sliding bearings, robot joints and model aircraft propellers simply couldn't fly without it.

Smooth raceway, low noise: 20 decibels quieter than gear bearings, so you won't be woken up by noise while sleeping in an air-conditioned room.

Low temperature operation: Low friction heat generation, the casing of an electric fan won't get hot even when running all night.